Phosphonic acid silica, 0.8 - 1.2 mmol/g - Metal Scavengers

Catalogue Number SIV0003

Synonym(s):

Functional Group Loading: 0.8 - 1.2 mmol/g

Particle Size: 35-200 µm

(Please enquire if you are interested in larg... Read More

- MSDS

- Request MSDS Information

- Typical Batch COA

- Request COA Information

- Request batch specific COA here

Product Description

Functional Group Loading: 0.8 - 1.2 mmol/g

Particle Size: 35-200 µm

(Please enquire if you are interested in larger particle sizes)

Industries: Battery and Electronics, Chemical, Catalysis, Refining, Metal Removal and Purification

High Performance Co Selective Scavenger for Battery and Electronics Applications

Streams - Co/Ni Streams at 10-7,000 ppm Co

Application - Selective separation of Co for recovery, recycling and purification

✓ Scavenger Process achieves << 1 ppm Co after treatment

✓ Highly efficient selective separation of Co from Ni solutions with high Co Loading capacity

✓ Separation/Recovery without using impregnated solvent chemicals

✓ No solvent exchange or other chemicals involved

✓ Reusability - Scavenger ready for use as received, no pre-treatment needed, easily regenerated

Examples of Selective Co Separation

Aqueous Co/Ni Streams with 10-1,000 ppm Co and Ni 1-50 g/L After treatment, < 1 ppm Co

Other Applications

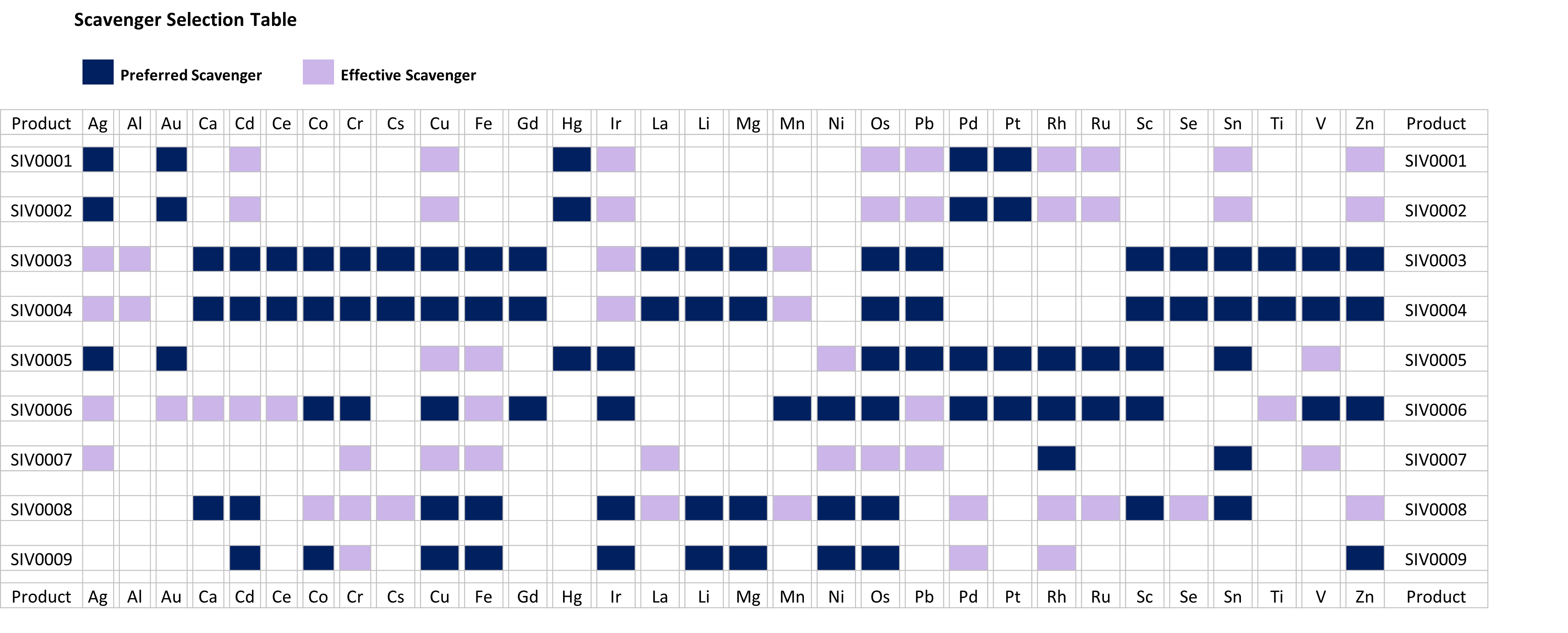

Metal Scavenger for but not limited to Ag, Al, Co, Cr, Cu, Ir, Li, Mn, Pb, Ru, Sn, Zn

Acid Functionalised Material for Organics Removal - Bases & Amines for Product Purification

Medium strength Solid Acid Catalysts including acylation, aldol, condensation, cyclisation, esterification, trans-esterification, isomerisation, ketalisation, polymerisation, rearrangements, dehydration/hydration

Metal and Organics Scavenger Benefits

✓ On Scavenger Treatment, Target removed to < 1 ppm (> 99% removal)

✓ Highly effective in all Organic, Aqueous and Mixed Solvent Streams

✓ No Loss of Customer’s High Value Product or Introduction of Impurities

Solid Acid Catalyst Benefits

✓ High Performance - Higher yields/turnover, greater selectivity, fewer side products

✓ High Stability - long catalyst lifetime, easily recycled/reused

✓ Operational Ease - Simpler Processes/Equipment with no phase separation, Lower Process Costs, Environmentally Friendly Processes - less toxic waste